Power: 0.75 kW

Product: 0.05 - 7 liters

Control: CVevo [Comfort]

With the modular quick-change systems, the DISPERMAT® CV3evo dissolver can also be used as: APS Bead Mill, TORUSMILL® TML Basket Mill, CDS Vacuum Dispersion System and SR Rotor-Stator Homogenizer.

The new, innovative all-rounder for the laboratory. In ergonomic design with process control and electric height adjustment.

Versatile laboratory dissolver for stirring, dispersing, vacuum dispersing, homogenising and fine grinding.

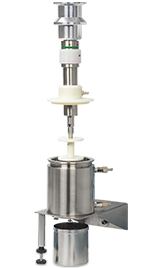

The DISPERMAT® CV3evo is a completely redesigned laboratory dissolver and impresses with a particularly ergonomic and compact design. It is equipped with an electric height adjustment and can be used for versatile tasks in the laboratory. The controller is situated in the new, high-quality stainless steel housing with an innovative glass panel and can be operated via the integrated, solvent-resistant membrane keyboard. The large colour screen shows all relevant process parameters. Thus the new DISPERMAT® CV3evo combines form and functionality in a new way.

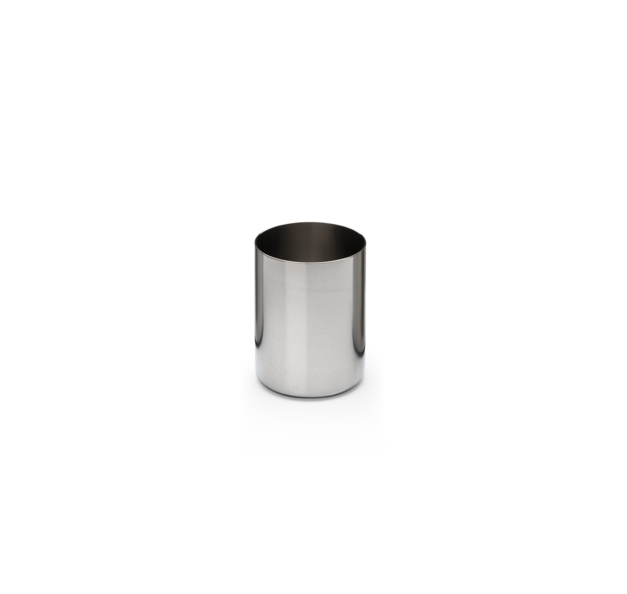

The sturdy central clamping system offers further comfort. With the clamping arms the dispersion container is centrally located and secured safely under the dissolver shaft. The integrated safety package in accordance with the machine directive 2006/42/EC provides reliable protection during the dispersing process. High grade design, certified quality and eliable technology characterise this all-rounder for the laboratory.

The DISPERMAT® CV3evo dissolver is suitable for multiple tasks in the laboratory and pilot plant:

OPTION: ACCESSORY

MODULAR SYSTEMS

Flexible. Powerful. Innovative.

HEIGHT ADJUSTMENT

ELECTRIC

Easy handling, functional design

DISPERSAFE®

TÜV CERTIFIED

Safety module (EN ISO 13849-1)

DISPERWHEEL®

SPEED ADJUSTMENT

with rotary pulse encoder

WORK SAFE

DIRECTIVE 2006/42/EC

integrated safety equipment

MADE IN GERMAN

SINCE 1972

quality, precision & durable technology

| DISPERMAT® type | Power kW | Speed rpm | Torque Nm | Stand type |

|---|---|---|---|---|

| Dissolver DISPERMAT® CV3evo | 0.75 | 0 - 20,000 | 0.8 | H1evo |

| Dissolver DISPERMAT® CVP3evo | 0.75 | 0 - 12,000 | 1.3 | H1evo |

| DISPERMAT® type | low-viscosity up to 500 mPs |

medium-viscosity 500 - 5000 mPs |

high-viscosity over 5000 mPs |

|---|---|---|---|

| Dissolver DISPERMAT® CV3evo | 0.05 - 7 liters 1.7 oz - 1.8 gallons |

0.05 - 5 liters 1.7 oz - 1.3 gallons |

0.05 - 2.5 liters 1.7 oz - 2.6 qt |

| Dissolver DISPERMAT® CVP3evo | 0.05 - 7 liters 1.7 oz - 1.8 gallons |

0.05 - 7 liters 1.7 oz - 1.8 gallons |

0.05 - 4 liters 1.7 oz - 1.1 gallons |

| DISPERMAT® CV3evo Stand H1evo |

|

|---|---|

| Dimensions W x H x D | 65 x 85 x 52 cm 26 x 33 x 20 inch |

| Height adjustment | electric |

| Container capacity | 0.125 - 10 liters 4.2 oz - 2.6 gallons |

| Container clamping range Ø |

5 - 35 cm 2 - 13.8 inch |

| Container height | 3 - 38 cm 1.2 - 15 inch |

| Weight | 37 kg 82 lbs |

The dissolver DISPERMAT® CV3evo is fitted with the CVevo technology

Versatile laboratory dissolver for stirring, dispersing, vacuum dispersing, homogenising and fine grinding.

CVevo technology

DISPERWHEEL®

infinitely variable speed adjustment with rotary pulse encoder

Large color display

indications of speed, torque, power, product

temperature, timer, peripheral speed and height of the dispersing tool

DISPERSAFE®

TÜV-certified safety module for convenient use of variable

container sizes without limit switches or mechanical contraption

Height measurement

adjustable working range for different container sizes

Connectivity

USB

Additional options

Data recording

the dispersion parameters are shown as curves on the colour

display, saved and can be exported as a CSV file

Switch off parameters

switch off function for temperature, speed, torque and

power

DISPERMAT® parameters

100 individual PRESET configurations for speed, time,

switch off parameters, etc.

Power compensation

net power calibration

Weight measurement

indication of weight from optional external scale

User management

configuration of user rights

Innovation made in Germany: With the modular quick-change systems, the DISPERMAT® CV3evo dissolver can also be used as: APS Bead Mill, TORUSMILL® TML Basket Mill, CDS Vacuum Dispersion System and SR Rotor-Stator Homogenizer.

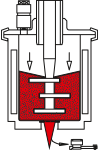

The addition of the modular APS bead mill converts the DISPERMAT® dissolver into a closed batch bead milling system.

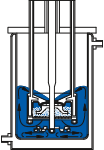

The addition of the modular TML basket mill converts the DISPERMAT® dissolver into an extremely efficient fine grinding system.

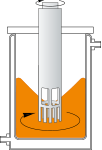

The CDS vacuum dispersion system enables the dispersion process in a completely closed system under vacuum.

Vertical high-performance rotor-stator systems for homogenizing, emulsifying, dispersing, mixing and dissolving.

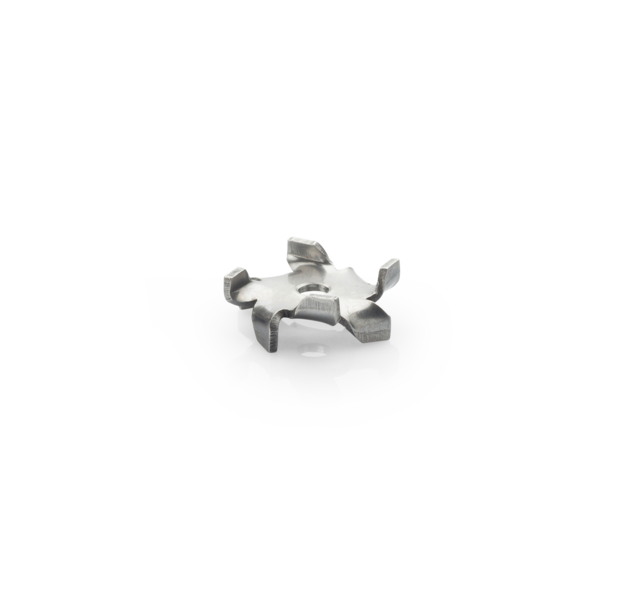

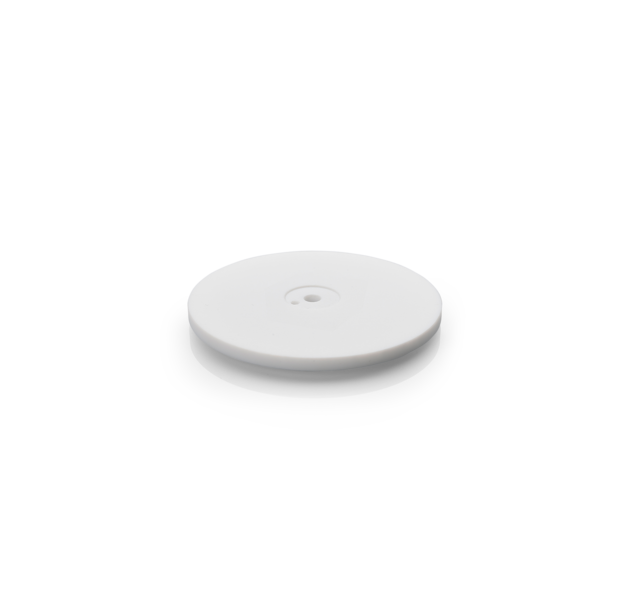

Dispersion containers and dissolver discs for the DISPERMAT® CV3evo disperser

| DISPERMAT® | Dispersion containers | dissolver discs Ø |

|---|---|---|

| Dissolver DISPERMAT® CV3evo | 0.125 - 10 liters | 20 - 90 mm |

| Dissolver DISPERMAT® CVP3evo | 0.125 - 10 liters | 20 - 90 mm |

We would be pleased to show you the impressive work section of our dispersing, mixing, stirring and fine grinding systems DISPERMAT® and TORUSMILL®.

Our skilled engineers are available at any time for personal advice.