Homogenizing, emulsifying, suspensioning, dispersing, mixing ...

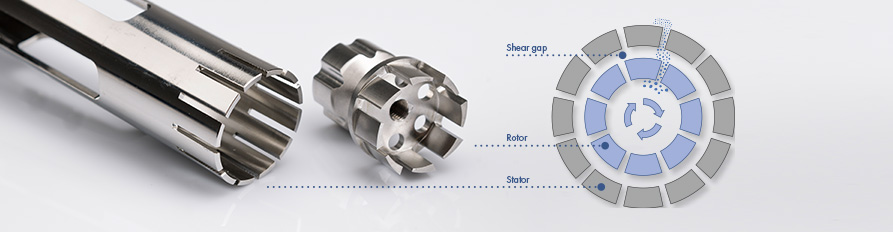

An emulsion is a finely distributed mixture of two liquids such as oil and water. The rotor-stator system is designed to overcome the interfacial tension to enlarge the interfaces by input of high mechanical energy with the rotor-stator system.

A suspension is a heterogeneous material composition consisting of a liquid containing finely distributed solids. The solids can be further processed by the rotor-stator to form smaller particles.

In the rotor-stator system the product is sucked axially into the dispersion head and pressed radially through the slots of the rotor-stator system. As a result, the product is accelerated and exposed to high shear stress and shear rates. In addition, the turbulence in the shear gap extensively mixes the emulsion/suspension. DISPERMAT® rotor-stator dispersers are available as immersion or inline systems.

Explosion-proof high shear mixers

All DISPERMAT® high shear mixers are also available in an explosion-proof version according to ATEX

We would be pleased to show you the impressive work section of our dispersing, mixing, stirring and fine grinding systems DISPERMAT® and TORUSMILL®.

Our skilled engineers are available at any time for personal advice.

VMA-GETZMANN develops, produces and markets high quality dispersers, mixers, stirrers, bead mills and basket mills. The innovative combination of technology and design as well as high quality are characteristic of our products. Of course, our mixing, dispersing and grinding equipment have integrated safety devices according to the EC Machinery Directive 2006/42 / EC.

Working together with the client our specialists optimize the essential process engineering and the most suitable system solution. Our involved development and design team comes with innovative ideas and long time experience in the mixing, dispersing and grinding technology. We produce with the most modern machine tools and therefore we guarantee a high standard of quality. We prove our expertise and reliability by also having an excellent after sales service.

We would be pleased to show you the impressive work section of our dispersers, mixers, stirrers, bead mills and basket mills for dispersing, mixing, stirring, homogenizing and fine grinding up to the nanoscale. Our skilled engineers are available at any time for personal advice.

The CV3evo line offers both a Basic and Advanced model which can be converted by optional accessory options to perform media milling, dispersing under vacuum, or homogenization by a rotor-stator and is equipped with new standard and optional adaptable features.

Download CV3evo Dispermat Dissolver Brochure to Learn More.

Dispermat® CV3evo PDFSince the foundation of the company the name VMA-GETZMANN has been synonymous with the production of high quality and innovative dispersers, basket mills, bead mills, mixers and stirrers for laboratory pilot plant and production. The integration of progressive technology with functional design as well as high quality, are characteristic of our products.

Andreas Stummer

Director, VMA-Getzmann USA/Canada

Phone: (240) 529-6659

Email: andreas.stummer@dispermat.com

Dipl.-Ing. Hendrik Fuchs

International Sales Manager

Phone: +49 2296 80355

Email: hendrik.fuchs@vma-getzmann.de

Lilli Schmidt / Лилия Шмидт

International Sales Manager

Phone: +49 2296 80317

Email: lilli.schmidt@vma-getzmann.de

Dipl.-Ing. Martin Keller

Sales Manager

Phone: +49 2296 80324

Email: mtk@vma-getzmann.de